The Right Firebrick for Every Build

The foundation of any kiln or furnace is the correct refractory material. At Sheffield Pottery, we’ve supported craftsmen, engineers, and artists for decades by supplying firebricks designed for efficiency, durability, and performance.

Insulating Firebricks (IFB / Soft Bricks): The Efficient Insulator

What They Are: Lightweight, porous bricks (≈4 lbs each) with high insulation value and low thermal conductivity. They heat up quickly and retain chamber heat, boosting fuel efficiency.

Applications:

- Electric and Natural Gas Kilns where clean atmospheres and rapid heat-up are desired

- Back-up insulation behind dense brick linings

- Projects where abrasion or chemical attack is not a concern

Visual ID: Pale yellow; soft enough to mark with a fingernail.

Grades: G20 = 2000°F, G23 = 2300°F, G26 = 2600°F, G28 = 2800°F

Workability: Can be cut with a standard carpenter’s hand saw for custom shapes.

Dense Firebricks: The Durable Workhorses

A) High Heat Duty Firebricks – The Economical All-Rounder

- Performance: Rated to Cone 31–32. Durable and cost-effective.

- Best Use: Backup linings, moderate operating temperatures.

- Note: Not recommended for highly abrasive conditions.

B) Super Duty Firebricks – The Premium Performer

- Performance: Rated to Cone 33–34. High strength, low shrinkage, excellent thermal shock resistance.

- Best Use: Primary hot-face linings in extreme conditions:

- Wood-burning, salt, and soda kilns

- Blast furnace stoves and open hearth checkers

- Glass tanks and other high-density applications

C) 70% Alumina Firebricks – The Industrial Specialist

- Performance: Ceramic- and chemical-bonded brick engineered for severe service.

- Best Use: Critical industrial applications requiring resistance to abrasion, slag corrosion, and thermal shock, such as:

- Electric arc furnace roofs

- Steel ladles (bottoms, sidewalls, slag lines)

- Rotary kilns (cement, lime), tundishes, torpedo ladles

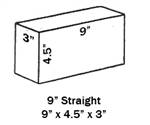

Shapes & Sizes for Complete Builds

A successful kiln or furnace requires more than rectangular bricks. Sheffield Pottery stocks refractory products in a wide array of shapes:

- Standard Straights: 9" × 4.5" × 2.5" and 9" × 4.5" × 3"

- Splits: Half-thickness bricks, 9" × 4.5" × 1.25", for fine adjustments

- Wedges & Arches: Precision-formed for curves, domes, and circles

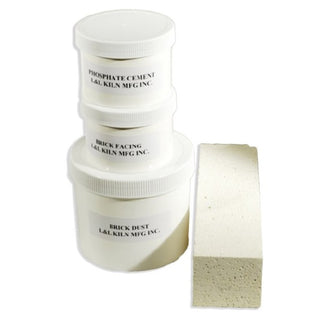

Beyond Bricks: Refractory Mortar, Castables & Kiln Furniture

In addition to firebricks, we supply:

- Dense refractory castables

- Insulating castables

- Conventional and silicon carbide kiln furniture

- Refractory mortar for bonding and sealing

These products ensure strength, insulation, and resistance under extreme thermal and mechanical stress.

Why Choose Sheffield Pottery?

- Expert Guidance: Our team helps you match the right firebrick—IFB, High Heat, Super Duty, or 70% Alumina—to your project’s requirements.

- Quality & Reliability: Products engineered for proven, long-term performance.

- One-Stop Supply: From bricks to refractory mortar and kiln furniture, we carry everything needed for kiln and furnace construction.

Build with Confidence: Selecting the right refractory materials is critical to safety, performance, and efficiency. Contact Sheffield Pottery today for expert support, fast shipping, and competitive pricing on every order.

| SOFT BRICKS | HARD BRICKS | ||||||||

| TEMP---> | G20/ 2000F |

G23/ 2300F |

G26/ 2600F |

G28/ 2800F |

HHD Cone 31.5 |

SD Cone 33.5 |

70%Alumina Cone 38 |

||

| Shape | Size in Inches | ||||||||

Straights |

2.5 | NC23 | NC26 | NC28 | LVHHD | LVSD | LVA70 | ||

| 3 | NC233 | NC263 | NC283 | LVHHD3 | |||||

Wedge #1 |

2.5 | NC20W1 | NC23W1 | NC26W1 | NC28W1 | LVHHDW1 | LVSDW1 | LVA70W1 | |

| 3 | NC203W1 | NC233W1 | NC263W1 | ||||||

Arch #1 |

2.5 | NC20A1 | NC23A1 | NC26A1 | NC28A1 | LVHHDA1 | LVSDA1 | LVA70A1 | |

| 3 | NC203A1 | NC233A1 | NC263A1 | NC283A1 | |||||

Arch #2 |

2.5 | NC20A2 | NC23A2 | NC26A2 | NC28A2 | LVHHDA2 | LVSDA2 | ||

| 3 | NC203A2 | NC233A2 | NC263A2 | NC283A2 | |||||

Arch #3 |

2.5 | LVSDA3 | |||||||

| 3 | |||||||||

Soaps |

2.5 | LVHHDSO | LVSDSO | ||||||

| 3 | |||||||||

Side Skews |

2.5 | LVHHDSS48 | |||||||

| 3 | |||||||||

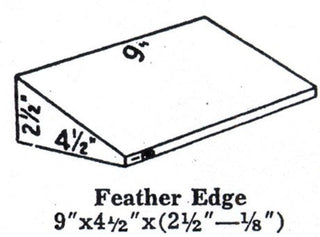

Feather Edge |

2.5 | LVSDFE | |||||||

| 3 | |||||||||

Splits |

2.5 | LVHHDSP | |||||||

| 3 | |||||||||

| |Note: there are no drawings of the 3 inch series bricks so here are the dimensions| | ||||

|---|---|---|---|---|

| 9" x 4½" x 3" SERIES | ||||

| 9"x4½"x3" Straight Small 9" Brick 9"x3½"x3" Split Brick 9"x4½"x1½" Soap 9"x3"x2¼" | No. 1 Wedge 9"x4½"x(3"-2¾") No. 2 Wedge 9"x4½"x(3"-2½") No. 3 Wedge 9"x4½"x(3"-2") No. 1 Key 9"x4½"x(4½"-4")x3" | No. 2 Key 9"x(4½"-3½")x3" No. 3 Key 9"x(4½"-3")x3" No. 4 Key 9"x(4½"-2¼")x3" | No. 1 Arch 9"x4½"x(3"-2¾") No. 2 Arch 9"x4½"x(3"-2½") No. 3 Arch 9"x4½"x(3"-2") Feather Edge 9"x4½"x(3"-⅛") | Neck Brick 9"x4½"x(3"-⅝") End Skew (9"-6⁹⁄₁₆")x4½"x3" No. 1 Side Skew 9"x(4½"-2¹¹⁄₁₆")x3" No. 2 Side Skew 9"x(4½"-1¹³⁄₁₆")x3" |

OUR PROCESS

Natural Sheffield Clay is mined on our property from as seen at one of the open clay pits. The Sheffield Clay deposit is located in Sheffield, Massachusetts, on U.S. Route 7 in the Southwest corner of Berkshire County.