At Sheffield Pottery making sure our customer is getting the best price on clay and an even better price on shipping, matters to us.

Help us help you by following these questions to get you the clay you want, where you want it, at a great price! For more than 1000 lbs or any quantity of clay for curb-side pick up from the Sheffield Pottery warehouse.

Ordering LESS than 1,000 lb of clay and want it delivered to me.

Ordering MORE than 1,000 lb of clay and want it delivered to me.

Pottery Clay

Clay manufacturing at Sheffield Pottery is completely unique in the industry. We have expanded our production line to include additional machinery setting a new standard for the clay industry. Dry clay ingredients are precisely weighed in our custom batching system, wet mixed in our world class Eirich mixer, and much or your clay is additionally processed in our Sweco 72” flow through separator and an iron filtration magnet which is used by no other clay maker in America. Read here on what Clay Type suits you best.

Notes on shipping during freezing weather: We must use our discretion as to when we can ship your clay and/or glazes to avoid it getting frozen. We will not ship wax resist when there is danger of it freezing. Quick video on how to deal with frozen glaze and clay will be handy! Clay orders in the cold months may experience delays. Watch a little video on Frozen Clays. How to fix Frozen Clays?

108300 Elaine's Crystal with Grolleg Porcelain Moist Clay c6 | 50Lb Box Delivered Price

$85.75

- Unit price

- /per

Liz's Light with Grog White Stoneware Moist Clay c6 - 50Lb Box - Delivered Price

$70.75

- Unit price

- /per

108300-Elaine's Crystal Grolleg Porcelain Moist Clay c6 | 50Lb Box Non-Delivered Price

$62.75

- Unit price

- /per

Mass Red with Grog Terra Cotta Earthenware Moist Clay - 50Lb Box - Delivered Price

$60.00

- Unit price

- /per

Liz's Light with Grog White Stoneware Moist Clay c6 - 50Lb Box - Non-Delivered Price

$47.75

- Unit price

- /per

Mass Red with Grog Terra Cotta Earthenware Moist Clay - 50Lb Box - Non-Delivered Price

$37.00

- Unit price

- /per

95400G School White with Grog Stoneware Moist Clay c10 - 50Lb Box - Non-Delivered Price

$43.00

- Unit price

- /per

95400G School White with Grog Stoneware Moist Clay c10 - 50Lb Box - Delivered Price

$66.00

- Unit price

- /per

108950-Elaine's Crystal Porcelain Moist Clay c10 | 50Lb Box Non-Delivered Price

$64.25

- Unit price

- /per

Berkshire White With Silica Sand Earthenware Moist Clay - 50Lb Box - Delivered Price

$63.50

- Unit price

- /per

95400 School White Stoneware Moist Clay No Grog c10 - 50Lb Box - Non-Delivered Price

$42.50

- Unit price

- /per

Mass Red No Grog Terra Cotta Earthenware Moist Clay - 50Lb Box - Delivered Price

$59.00

- Unit price

- /per

Mass Red No Grog Terra Cotta Earthenware Moist Clay - 50Lb Box - Non-Delivered Price

$36.00

- Unit price

- /per

You’re viewing 1-50 of 80 products

SHEFFIELD POTTERY CLAY : AMERICA’S PREMIER CLAY MAKER

Sheffield Pottery clay is unparalleled in its quality and consistency. We use state-of-the-art equipment to create a perfect clay body for any application. When you order Sheffield Pottery Clay it arrives with two 25-pound sleeves in a 50-lb box. (and yes! we twist-tie the bags!) The clay has been blended and pugged in our state-of-the-art de-airing pugmills with just the right amount of water so it is smooth and soft and ready to use right out of the box.

AT SHEFFIELD POTTERY WE TAKE GREAT PRIDE IN OUR CLAY. THAT IS WHY WE ARE CONSIDERED AMERICA’S PREMIER CLAY MAKER!

FREQUENTLY ASKED QUESTIONS

There are three main types of pottery clay: Earthenware, Stoneware, and Porcelain.

Clay for all types of ceramics are blended from various types of clay and minerals that impart different firing and handling characteristics.

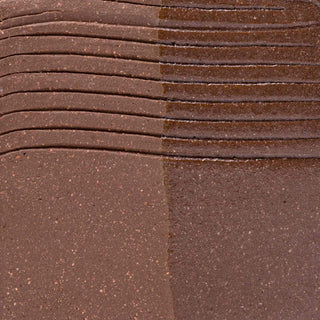

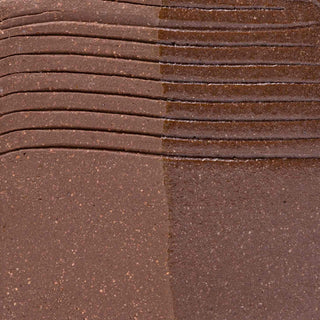

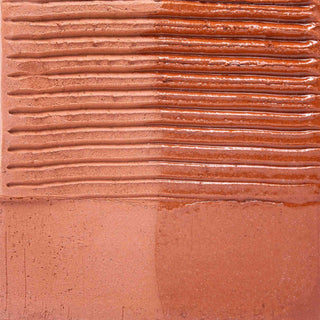

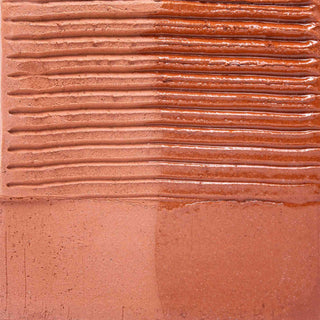

Earthenware: Earthenware clay is "low-fire" so you will fire around Cone 05 depending on the formula. These clay bodies include classic terra-cotta and low-fire talc and no-talc white clays often used in schools. Earthenware clay can not technically be vitreous (water-tight) on its own so generally, these clays are used for decorative items and sculpture.

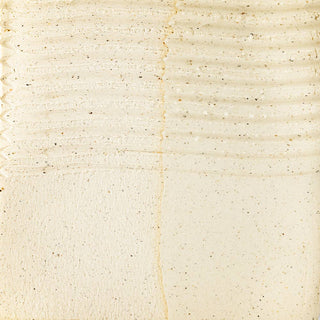

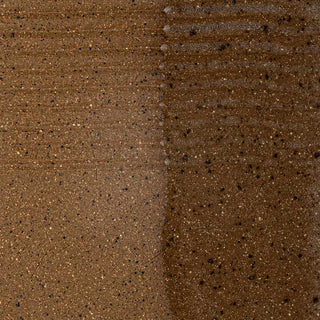

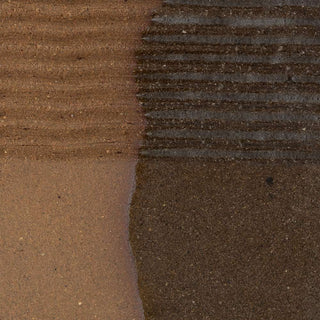

Stoneware: Stoneware clay is mostly "mid-fire" so you will fire at cone 5 or cone 6. We also offer a selection of "high-fire" cone 10 stoneware bodies as well. Stoneware is your choice to make functional ware in electric, gas or wood kilns. Any properly fired stoneware clay will be vitreous enough to hold water even without a glaze. Stoneware is clay in the majority of good-quality, studio pottery. We offer a range of light and dark stoneware clay bodies to suit your taste to a t! Choose "white stoneware" for clay nearly as white as porcelain but with the handling characteristics of a friendly stoneware.

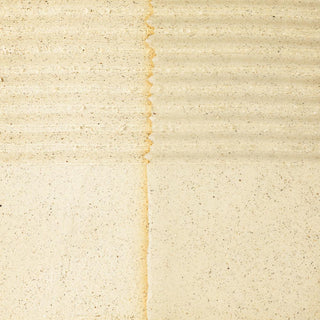

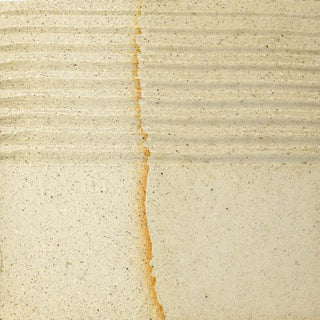

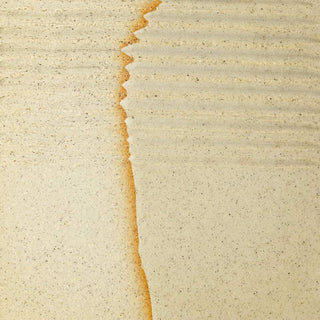

Porcelain: Porcelain pottery clay offers the whitest color of the mid-fire and high-fire clays. Fine china and bone china are made with porcelain clay with a lot of kaolin. Our porcelain clay bodies are blended with other clays to give you the best handling characteristics while still maintaining it's a natural beauty. Compared to stoneware, porcelain is considered "short" meaning it is less tolerant to being worked on the wheel. Throw quickly and with as little water as possible to overcome this. If you can throw very thin walls you can expect to find some translucency! Traditionally porcelain has been for cone 10 only but we offer excellent cone 6 porcelain as well so that you can use it in your electric kiln!

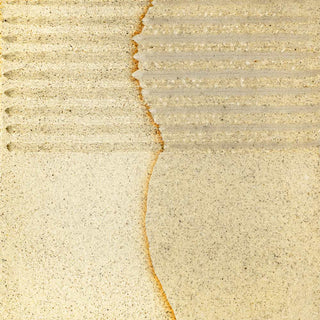

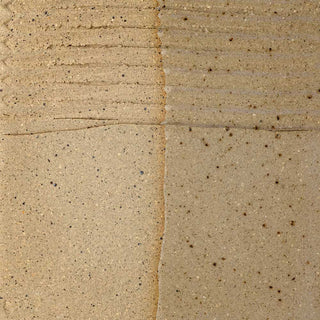

You will notice that we offer many of our clay bodies with or without grog. Grog is ground-up of pre-fired clay or sand. The addition of grog in clay gives the claymore "tooth." The tooth will make it much easier to throw on the wheel. Grog also limits the shrinkage of clay from wet to bone dry so when you join handles or are hand-building you will have better success. Grog also gives the clay greater resistance to thermal shock if you raku or pit fire. Our specialized Sculptural, Architectural, and raku clays have a lot of grog but our regular clay bodies have just enough to give you that tooth without it being overly gritty on your hands.

OUR PROCESS

Natural Sheffield Clay is mined on our property from as seen at one of the open clay pits. The Sheffield Clay deposit is located in Sheffield, Massachusetts, on U.S. Route 7 in the Southwest corner of Berkshire County.