L&L VENT-SURE DOWNDRAFT KILN VENT SYSTEM

Now you can also add vent control to your vent on kilns with L&L Dynatrol Controller !!!

The vent control allows you to automatically control the operation of the Vent-Sure kiln vent with one of the outputs from the DynaTrol. ( It may not be used with kilns with powered bottoms because the same output on the control is used)

WHAT DOES THE KILN VENT DO?

The L&L Vent-Sure downdraft kiln vent system is designed to pull air contaminated with carbon monoxide and other fumes including those of volatile metals, decals, sulfur oxide, and others in a down draft fashion out of the kiln and then vent it outside or to a central vent system.

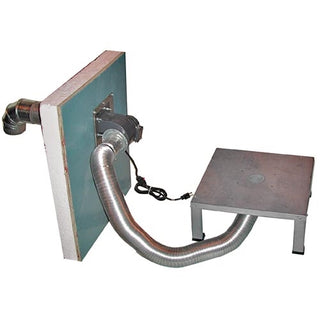

This includes the motor, an 8 foot cord with a rocker type On/Off switch mounted in line in the cord, the inlet duct attached to the motor, the wall mounting bracket, a 90 degree elbow for mounting on the end of the outlet pipe (to keep rain water out), the Bypass Collection Box for attaching to the kiln stand or kiln side along with mounting hardware for mounting to an L&L kiln stand and one section of 15 foot flexible aluminum duct with hose clamps.

Will the fumes coming through the downdraft kiln vent system damage my plants, the neighborhood pets or disturb the local environment?

No. The fumes and the gases coming from the kiln have been diluted with enough fresh air to make them safe for the environment. (L&L NOTE: Do not, however, place the outlet of the vent below an open window. Also we have heard of plants near the vent outlet being affected by the vent fumes so keep this in mind when locating vent outlet).

Will using the vent cause my firing to take longer?

The L&L downdraft kiln vent system pulls only a very small amount of air out of the kiln, so very little heat is removed and firing times will change very little. For some kilns, a high firing may take a little longer. The insulation value and the number of air leaks in the kiln also determine the length of the firing. (L&L NOTE: We have seen vents overpower smaller kilns - so it is important to adjust the amount of venting in some cases. On the other hand an example of an e23T 7 cubic foot kiln firing an 85 pound load on Fast Glaze program to cone 8 took 7 hours and 4 minutes with a vent on and 6 hours and 24 minutes without a vent. The vent was on the whole time).

WHAT IS INCLUDED WITH THIS DOWNDRAFT KILN VENT SYSTEM?

One (1) wall-mounted blower mounted on a bracket

with vent pipe to go through outside wall and a Motor

Inlet Duct. An 8 foot power cord with an attached

On/Off switch plugs into a 120 volt standard receptacle.

One (1) Bypass Collection Box to be mounted to the

kiln or on the kiln stand, with mounting hardware.

One (1) length of flexible aluminum ducting (expands

to 8 feet).

Two (2) hose clamps.

One (1) 4” diameter 90 degree elbow (for outside the

building.

MOUNTING OF THE VENT BLOWER

The vent blower is mounted on an outside wall or window, or near an existing exhaust ducting system. (With the special “Multi-Mounting Bracket” the vent motor may be mounted on the floor or a wall with the outlet pointing up and then connected to an existing vent system or 4” wall outlet). The Bypass Collection Box mounts to the kiln either on the side of the bottom kiln section, or underneath the kiln on the kiln stand. (Jupiter and Easy-Fire kilns have studs on the stands to accept this box). It covers holes drilled through the brick. The blower is then connected to the Bypass Collection Box with the flexible aluminum duct, and the blower is plugged into a 120 Volt receptacle for operation.

NEGATIVE PRESSURE

When operating, the L&L downdraft kiln vent system creates a negative pressure (partial vacuum) in both the Kiln and the flexible aluminum duct, so that fumes are pulled out of the kiln as well as out of the flexible duct. No taping of joints is necessary (although it is OK to do this). Should a leak develop in the duct, air will be sucked into the duct rather than blown out of it. This is a major advantage of the L&L Vent-Sure vent system.

AIR INLETS

Normally no holes are necessary in the lid brick for fresh air inlet as the leaks in most kilns allow sufficient fresh air to be drawn into the kiln through element end penetrations, peephole plugs, leaks between the lid and the top section, leaks between sections, and leaks between the bottom section and the bottom brick. Holes may be drilled in the lid brick at any time if later found necessary. If you decide to drill holes in the lid start with a 1/4” diameter hole drilled about 4 inches in from an edge of the lid (and then add other holes as necessary in the back of the lid and then on the sides). BE SURE NOT TO DRILL ANY HOLES WITHIN 6” OF THE THERMOCOUPLES. You do not want cold air flowing onto the thermocouples.

HEAT IS AWAY FROM MOTOR

Other important advantages of the L&L Vent-Sure downdraft kiln vent system are that the motor, being mounted away from the kiln (and the floor), will not pick up brick dust (which could destroy the motor), will not cause the kiln to vibrate (which can cause ware to move, damage to the kiln, and misfiring of cones on a Dawson Kiln Sitter) and will not be affected by the heat of the kiln. Because the motor is not under the kiln you can turn the vent off whenever you want. It is not necessary to keep it on to cool the motor as in some other kiln vents.

CUSTOMER REVIEWS - Q&A

Got a question about this product? Ask it here and get a response from our staff and also input from the Sheffield Pottery community!