Skutt KM1231-3PK Electric Kiln

Here is the high volume Cone 10 power you’ve been looking for.

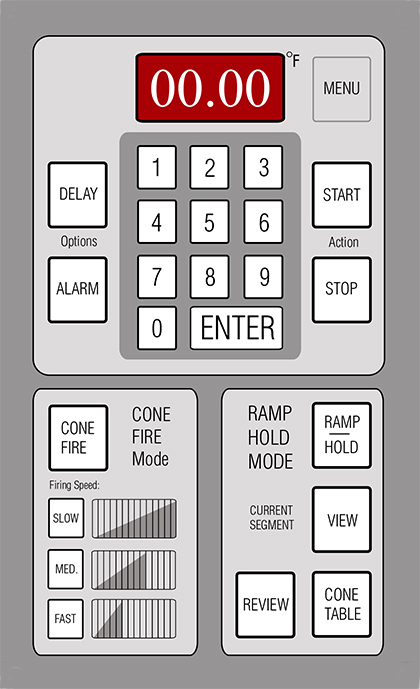

Finally, a Skutt electric kiln line designed specifically for volume production and fast turnaround of high mass loads. The Skutt 1231 PK has the power and industrial components to go straight to Cone 10 with a full load of tile or stoneware – no slow struggling to reach the final temperature. The standard KilnMaster controller gives you the options of Cone Firing or selecting your own 8-segment Ramp/Hold firing programs. The combination of direct wiring, heavy duty elements, connectors and relays, plus traditional Skutt stainless steel and firebrick construction results in a large electric kiln that will last for years of constant use. Among the most powerful on the market today, the line was designed at the request of Skutt customers.

Finally, a Skutt electric kiln line designed specifically for volume production and fast turnaround of high mass loads. The Skutt 1231 PK has the power and industrial components to go straight to Cone 10 with a full load of tile or stoneware – no slow struggling to reach the final temperature. The standard KilnMaster controller gives you the options of Cone Firing or selecting your own 8-segment Ramp/Hold firing programs. The combination of direct wiring, heavy duty elements, connectors and relays, plus traditional Skutt stainless steel and firebrick construction results in a large electric kiln that will last for years of constant use. Among the most powerful on the market today, the line was designed at the request of Skutt customers.

![]() Now all 10 and 12-sided KilnMaster Kilns come standard with a Skutt Lid Lifter.

Now all 10 and 12-sided KilnMaster Kilns come standard with a Skutt Lid Lifter.

Chamber Capacity

| DEPTH | OPENING WIDTH | OPENING LENGTH | CU. FT. | TEA BOWLS |

|---|---|---|---|---|

| 31 in | 28 in | 28 in | 11.6 | 54 |

Approximately 28 in. x 28 in. opening and 31 in. high: 11.6 cubic feet, 54 bowls.

The Skutt KM1231-3PK Single Phase Electric kiln includes the KilnMaster controller built in.

Other standard features include:

- 2 year limited warranty, elements excluded

- Encapsulated Type K thermocouple

- Solid State Relays

- Industrial gauge wiring

- Compression connectors on feeder wires

- Larger, swing away, air-cooled switch box

- Multi-sided design

- Stainless steel jacket

- Sectionalized construction

- Two lift handles on each section

- Sealed, dust-free lid with full-floating hinge

- Three types of exposed, pinned elements for optimum balance

- Reversible top and bottom slabs

- Stand included

- Peep plugs

- UL listing

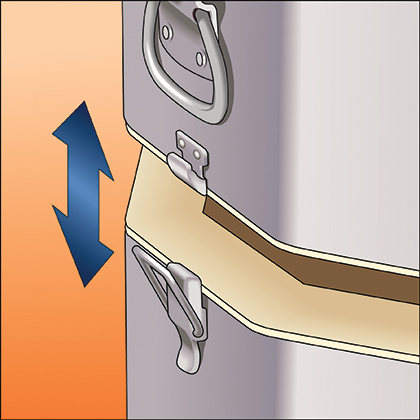

The New Lid Lifter makes our 10 and 12-sided lids some of the lightest on the market. In fact you can now lift them with just a finger. The lid brace has been redesigned for added strength and now has 2 positions. The innovative Center Pivot Design distributes the force on the lid across 2 points as opposed to only one.

It ships fully assembled on the kiln. And unlike some other brands there is no awkward loading of the springs required. The kiln remains completely sectional for moving and repairs. The lid can be effortlessly and safely detensioned by simply raising the lid and sliding out the tension rod. It really is that easy!

- So Light You Can Lift It With A Finger

- New Reinforced 2 Position Lid Brace

- Innovative Center Pivot Design

- Ships Fully Assembled

- No Tension Loading Required

- Does Not Affect Sectional Construction

- Ceramic Handle Remains Cool

- All Corrosion Resistant Parts

- Easy To Install Upgrade System

- 3 Position Lid Latch and Prop Mechanism

- Easy View optional accessory

Features:

Sophisticated, Yet Easy to Use:

- Write your own firing programs with up to 32 Segments using Ramp and Hold. Now you can store up to 12 programs.

- … or use the tried and true factory set programs in ConeFire Mode

- Built in Diagnostics give you or our technicians the ability to diagnose kiln problems with just a few button presses.

- New Safety Features help prevent accidental starts and overfires.

- New software keeps track of your Firing Costs and the Number of Firings

- Fuse Glass, Slow cool Cone 6 Glazes, Grow Crystals…whatever you want to program this controller can handle.

Current Sensing Technology:

Skutt is one of the few brands that installs a Current Sensor in every KilnMaster Kiln. This allows you to read the Amperage of each section of the kiln as well as the Voltage and Voltage Under Load.

Now with the touch of a few buttons you can give those readings over the phone to your kiln repair technician so they can troubleshoot the problem and make sure they have the correct parts when they come out for the repair. This Saves Time and Money.

Prior to the use of these current sensors someone would have to come to your house and test the amperage and voltage inside the control box with live wires exposed. This system is Much Safer.

Sectional Design:

Sectional Design is a good idea on so many levels.

Moving:

Imagine trying to move a kiln into the basement or through a narrow door without being able to break it down into sections.

Repair:

No more standing on your head in the kiln to replace those bottom elements or removing every brick in the kiln to get to the one you want to replace. Just remove the control box, unhook the buckles and place the section you want to work on on a table.

Replacement:

We hope nothing really bad happens to your kiln … but … if it does, isn’t nice to know you can replace one bad section instead of the whole kiln?

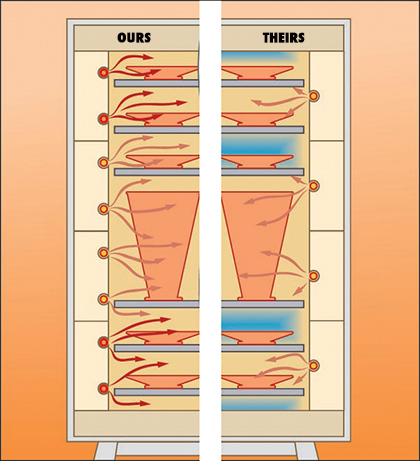

Balanced Elements

A large amount of the heat you lose in your kiln passes to through the lid and slab of your kiln. To compensate for this, Skutt directs more heat to these areas when they design the elements. The fact that we have twice the element grooves in our kilns gives us more design flexibility than some of our competitors.

It also gives you more loading options since it is always recommended to have at least one element radiating between each layer of shelves. Oh and by the way, twice the grooves means you get twice the amount of element wire, which means each element doesn’t have to work as hard, which means longer element life! Whew!

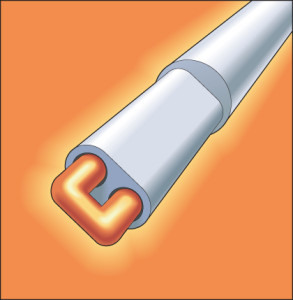

The Thermocouple

- Exposed Thermocouple equals faster reaction time and higher accuracy.

- Inexpensive, plus we give you an extra one when you buy your kiln.

- Easy and quick to replace.

- Type S (Platinum) Upgrades Available.

Skutt KM1231-3PK Kiln Specifications:

CUSTOMER REVIEWS - Q&A

Got a question about this product? Ask it here and get a response from our staff and also input from the Sheffield Pottery community!