VPM30TE TILE EXTRUDING PETER PUGGER PUGMILL

Here you can order a vacuum de-airing VPM30TE Pugmill Mixer by Peter Pugger at Sheffield Pottery Ceramic Supplies.

Runs on either 208 or 240 volt

Will not run on 115/120v

From its inception in 1984, the VPM-30 caught the attention of the industry as the first and only Vacuum Deairing Mixing Pugmill of its kind. Since that time, Peter Pugger has incorporated several advancements into its extension line of Vacuum Dearing Mixing Pugmills. We are proud to announce the newly renovated VPM-30TE with its “chainless”, maintenance free geardrive system, state-of-the-art VFD technology, updated vacuum chamber and aggressive auger design that embellishes the quality and performance that our customers around the world have come to expect.

-The Vacuum Power Wedger combines the capability of batch mixing with

the convenience of pugmill output and the ease of vacuum deairing.

-All your scrap goes right back into the hopper and is recycled, vacuum deaired and pugged.

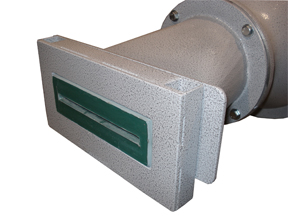

This tile extruding version of the VPM30 is:

VPM-30 with the following modifications:

- Variable Speed

- Upgraded 2Hp Motor

- Reinforced Structural

- Modified SST Auger

- Tile Nozzle

- SST Tile Nozzle Guides/Hardware

Ship Weight : 580lbs

FEATURES

Stainless Steel: Shaft,

augers and paddles of stainless steel, along with aluminum mixing and

pugging chambers, make for rust-free clay processing.

Removable Blades: The mixing blade/auger assembly is removable for ease of cleaning.

Large Hopper: The 8" x 8" hopper door allows for easy loading of up to 85 Ibs. of clay per batch.

Batch Mixing Capability: Full batch mixing and blending capability allows for moisture adjustment before pugging.

Pugmill Output: Switch to PUG after a batch is completely mixed, and the Power Wedger unloads itself in the form of 3" diameter deaired logs.

Vacuum Deaired:

Each batch can be deaired by starting the vacuum pump when the load is

mixed. Air is removed during the last stage of mixing, leaving an

air-free product when pugged out.

Sealed Chamber: Leaving moist clay in the Power Wedger is not a problem. All the openings are sealed so clay will stay moist indefinitely.

Variable Speed Control:

This allows the operator the ability to speed up or slow down the

pugmill. This is especially useful when extruding through dies. Because

of the back pressure generated by a large amount of clay being forced

through a small orifice, the speed control allows the operator to slow

the pugging as required. In turn, perfect deaired configurations are

easily extruded through the Pugger-Mixer. There are additional

advantages if you are a "single potter studio". The ability to slow the

pugging allows for time to place pugged clay into containers or bags.

On Wheels: The VPM-30 comes with 6" diameter wheels. It is easily transported for cleaning or storage.

Work Surface:

The motor and drive are enclosed for protection, cleanliness and

safety. A 14" x 20" cleanable work surface is provided on top for

convenience of the operator while loading.

CAPABILITIES

The

Vacuum Power Wedger is the most versatile studio clay processing

machine on the market today. It can perform a variety of functions

efficiently, transforming clay in any form to a usable product.

Some examples:

-

Mix moist clay from powder and water.

-

Reclaim scrap-wet or dry.

-

Blend two or more different bodies.

-

Add materials (wet or dry) to an already moist body.

-

Adjust moisture of an already wet body.

-

OR just warm up a batch of clay.

When the clay is adequately mixed, it can be deaired with vacuum and pugged out in the form of logs ready for use.

SAFETY

It

is not necessary to continuously hand-feed the Vacuum Power Wedger as

with standard pugmills. Load a full batch, close the lid and turn it on

- this eliminates exposure to moving blades. The Power Wedger shuts off

automatically when the lid is opened. All machines are equipped with a

thermal overload for protection against overheating.

Cleaning

is necessary only to avoid cross-contamination. Since the machine is

completely sealed, it can be left for long periods of time without the

clay drying out.

SHIPS FOB Ukiah, CA 95482, USA

- Maximum Batch Capacity: 85 pounds

- Pugging Rate: 800 lbs. per hour

- Mixing Rate: 240 lbs. per hour

- Dimensions: 56″L x 24″W x 33″H

- Crafted Weight: Aluminum Version – 470 lbs. (Ships LTL Trucking)

- Hopper Door Size: 8″ x 8″

- Pug Size: 3″ round/2″ x 10″ Tile Nozzle & Adapter

- Electrical: 2 HP 1-phase, 11 amps at 240V

- Vacuum Pump: 1/2 HP, 3 amps at 240 volts