Hard Bricks : Dense Firebrick Refractories

Dense Fire Bricks are also known simply as hard brick. These bricks are very heavy at about 8 pounds each. They are highly refractory with high service operating temperatures. The color varies some but are all yellow tan to light orange in color. Dense Fire Bricks are also known simply as hard brick. These bricks are very heavy at about 8 pounds each. They are highly refractory with high service operating temperatures. The color varies some but are all yellow tan to light orange in color.

Hard Fire Bricks are resistant to abrasion and chemical atmosphere so they are found in the fire boxes of wood and salt kilns, and power plants.

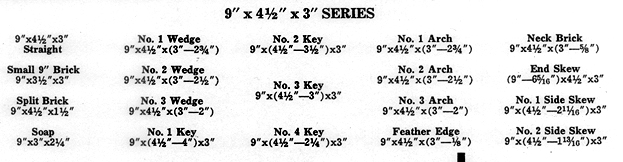

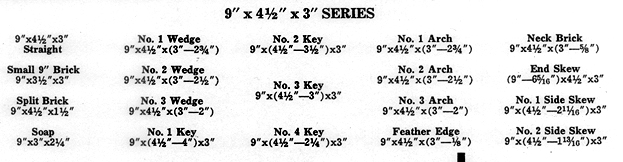

There are many stock shapes for building complicated forms and arches.

Even fairly simple kilns and furnaces require a combination of different shapes to build.

Refractory

shapes include precast cement and fused or sintered refractory products

that are formed prior to installation in furnaces, boilers or other

high temperature equipment.

Refractories

are hard, heat resistant materials and products such as alumina,

silicon carbide, fire clay, bricks, precast shapes, cement or

monolithics and ceramic kiln furniture. Ceramics and refractories have

high melting points are suitable for applications requiring wear

resistance, high temperature strength, electrical or thermal insulation

or other specialized characteristics.

Refractory fire bricks, blocks, and tiles are stacked to form insulating furnaces, boilers or other thermal process vessel walls. The hard bricks are usually cemented together with refractory mortar.

Shown above right is a new gas kiln made with fire bricks from Sheffield

Pottery by the late John Zentner of New Hampshire Potters Guild.

Call to special order any firebrick sizes not shown. Discounts are available when ordering 500 or more fire bricks.

HARD BRICKS

CHOOSE HARD BRICKS FOR OUTDOOR APPLICATIONS : Wood Kilns. Soda Kilns usually require 70% alumina hard brick below.

Give us a call to speak to one of our experts to help pick the correct bricks for your project.

HIGH HEAT DUTY -

Economical high-duty firebricks will go to cone 31-32. Suitable for backup

linings, and other areas that encounter moderate operating

temperatures. Not suggested for abrasive conditions. (equivalent to

Empire) 2 1/2” except where * (3”)

SUPER DUTY -

Exhibits high

strengths and low shrinkage, good resistance to thermal shocks. Can be

used as the inside lining of kiln. Will go to cone 33-34. (equivalent

to Clipper) 2 1/2” except where * (3”)

70% ALUMINA -

A chemical and

ceramic bonded 70% alumina brick designed for the following

applications: Electric furnace roofs, ladle bottoms, side walls and

slag lines, rotary kilns, cement kilns, torpedo ladles, tundishes, and

hot zones of lime kilns. Cone 38.

Note: there are no drawings of the 3 inch series bricks so here are the dimensions:

|

|

Dense Fire Bricks are also known simply as hard brick. These bricks are very heavy at about 8 pounds each. They are highly refractory with high service operating temperatures. The color varies some but are all yellow tan to light orange in color.

Dense Fire Bricks are also known simply as hard brick. These bricks are very heavy at about 8 pounds each. They are highly refractory with high service operating temperatures. The color varies some but are all yellow tan to light orange in color.